Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Модель: LJ-10

марка: SIHAI

Подробности Упаковки: Seaworthy packing

производительность: 200SETS/YEAR

транспорт: Ocean

Место происхождения: HENAN

Поддержка о: 200SETS/YEAR

Сертификаты : CE ISO

Код ТН ВЭД: 8419409090

Порт: Lianyungang,Qingdao,Shanghai

Вид оплаты: L/C,T/T,Western Union

Инкотермс: FOB,CIF

high oil yield waste tyre recycling plant

Equipment Technical parameters:

|

NO. |

ITEM |

|||

|

1 |

MODEL PYROLYSIS PLANT |

LJ-8

|

LJ-9

|

LJ-10

|

|

2 |

RAW MATERIAL |

waste plastic, waste rubber |

waste plastic, waste rubber |

waste plastic, waste rubber |

|

3 |

STRUCTURE |

Horizontal rotation |

Horizontal rotation |

Horizontal rotation |

|

4 |

10-HOUR HANDING CAPACITY/PER BATCH |

5 tons of raw material |

8 tons of raw material |

10 tons of raw material |

|

5 |

10-HOUR OIL PRODUCTION |

2.25 tons of oil |

3.2tons of oil |

4.5 tons of oil |

|

6 |

WORKING PRESSURE |

Room pressure |

Room pressure |

Room pressure |

|

7 |

HOST SPEED |

0.4r/m |

0.4r/m |

0.4r/m |

|

8 |

POWER |

12.0KW |

14.0KW |

15KW |

|

9 |

COOLING |

Water cooling |

Water cooling |

Water cooling |

|

10 |

COOLING WATER CONSUMPTION |

4 |

4 |

6 |

|

11 |

RATATION MODE |

External gears |

External gears |

External gears |

|

12 |

HEATING MODE |

Directly heating |

Directly heating |

Directly heating |

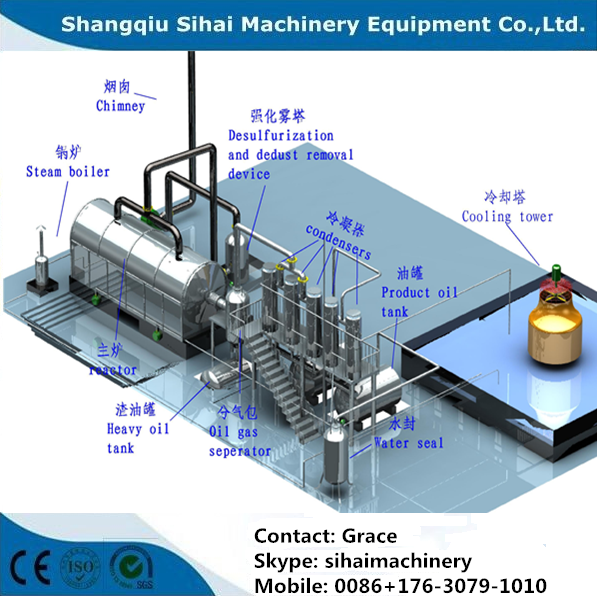

2. Working process Of high oil yield waste tyre recycling plant :

First, the raw materials are put into the reactor, and then seal the feeding in door, later start the machine and the reactor will be rotating and heated by coal, natural gas, wood or electricity. When the temperature reaches the degree of 250 to 280, we will get the crude oil, the oil steam will be continuous produced until the temperature reaches 350-460°C; oil steam will flow through oil gas separator, light component will enter the condensers and meanwhile the heavy oil will be discharged automatically into in heavy oil tank. The liquefied part will be condensed as crude oil, and the part which cannot be liquefied will be transferred by the water seal back to the burning chamber to be reused as heating material.

3. End of Product from high oil yield waste tyre recycling plant :

NO.

Name

Percentage

Usage

1

Tyre oil

40%~45%

* can be sold directly as fuel.

* can be refine to diesel and gasoline by oil distillation plant

2

Carbon black

37%

* can be sold directly.

* can be refined by carbon black processing machine to make it finer (1500mesh finer).

*can be made into pellet by pellet machine

3

Steel wire

13%

*can be sold directly as steel or iron.

4

Waste gas

5%

* can be recycled to heat up the reactor

4. Installation: We will be in charge of arranging our engineer to go to your place to guide the installation and train your workers how to operate the high oil yield waste tyre recycling plant ,and you will be in charge of the food, accommodation and round air tickets.

5. Land requirement: 300sq meters(10m*30m)

6. Exporting Experience:

America:

Brazil, Canada, Colombia, USA,

Middle East:

Dubai, Iran, Jordan, Saudi Arabia, Turkey

Europe:

Albania , Bosnia and Herzegovina

Asia:

Afghanistan, India, Malaysia, Pakistan, Philippines, South Korea, Vietnam, Myanmar

Africa:

Ghana, Mozambique, Zambia

Группа Продуктов : Растительных Отходов Шин Пиролиз

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.